Specialisation

Manufacturing process

Although specialised in aluminium tanks for the transport of hydrocarbons, our vehicles are also manufactured in materials such as stainless steel and are used to transport other products. These tanks combine design and standardisation, and boast an advanced manufacturing and commercialisation process.

No matter whether it is the semitrailer type tank or the rigid tank, a COBO tank is synonymous with Experience, Technology and Quality

Click on the type of tank to view the range of vehicles available

Our R+D+i at your service

ENGINEERING AND DESIGN

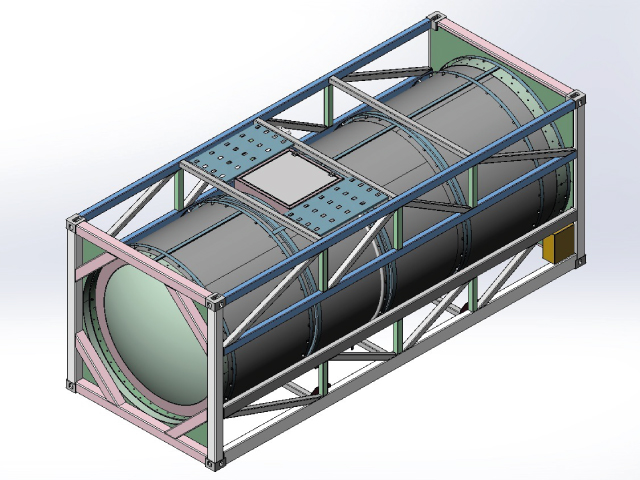

Our own engineering uses the most advanced procedures in the design and structure calculations, which allows us to simulate all the designs before manufacturing. These tools, which are constantly being up-dated, are at the forefront of technology, fundamentally improving our processes and providing high quality technical solutions.

Diversity

Other Products and Services

As we strive to constantly adapt to the market and to the needs of our clients, as well as our tanks, COBO also offers a wide range of complementary products and services:

- Maintenance, after-sales service and repairs of our own units and those of other manufacturers.

- Production of dish ends and baffles, adapting to the needs of the client.

- High degree of specialisation in the manufacturing and maintenance of the containers.

- Advanced engineering services for companies which manufacture large pieces of equipment.

Cobo Worldwide

CONTACT

Without losing our roots, we at Cobo have managed to commercialise our tanks in all five continents. However, our know-how remains wholly at our plant in Guarnizo, where the management and the entire workforce play their part to ensure that Cobo Tanks continues to be synonymous with “Experience, Technology, and Quality”.