ENGINEERING AND DESIGN

ENGINEERING AND DESIGN

COBO engineering has the most advanced design and structural calculation procedures, which means they can simulate all the designs before manufacturing. These tools, which are constantly being up-dated and which are at the forefront of the latest technology, have improved their processes notably and provide high quality technical solutions.

Carbon footprint

COBO is a Company firmly convinced of future sustainability and therefore, in the general manufacturing process of the vehicle, always chooses the raw materials (aluminum, axles and suspensions, equipment, paint, tires … etc.) Focus on having the least footprint of carbon possible. Also, during the manufacturing process the shape of the vehicle, work procedures are used that also generate the least carbon footprint, seeking the greatest energy and environmental efficiency in the entire process.

95% of the material used in our production process is aluminum, 99.9% of all the remaining material being recycled. As for the hazardous waste from the painting process, such as the use of filters, absorbers and water with hydrocarbons, we have distillation systems and the most appropriate treatments of the materials used in these processes.

During the useful life of the vehicle, we work daily to reduce the weight of the vehicles in order to transport more products each way and increase their aerodynamics, reducing considerably the fuel consumption of the fleets.

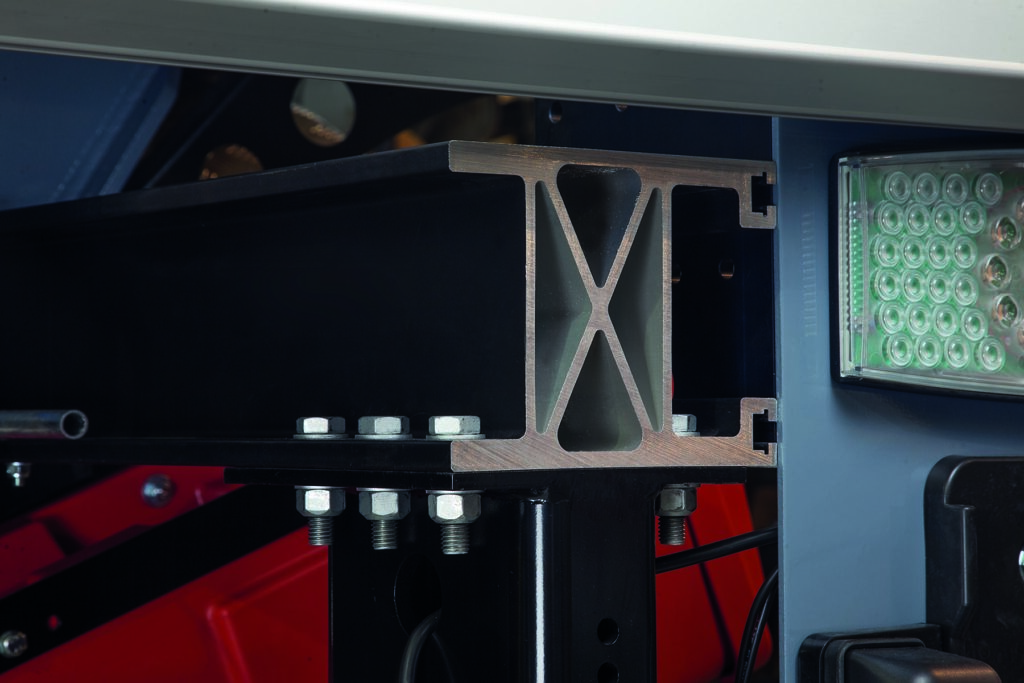

Extruded profiles

One of the most significant characteristics of our Tankers is the intensive use of extruded aluminum profiles in the most critical areas of the structure. All the profiles are designed by our Engineering, made in special aluminum alloys with what is achieved a great structural robustness and tested in the most demanding conditions.

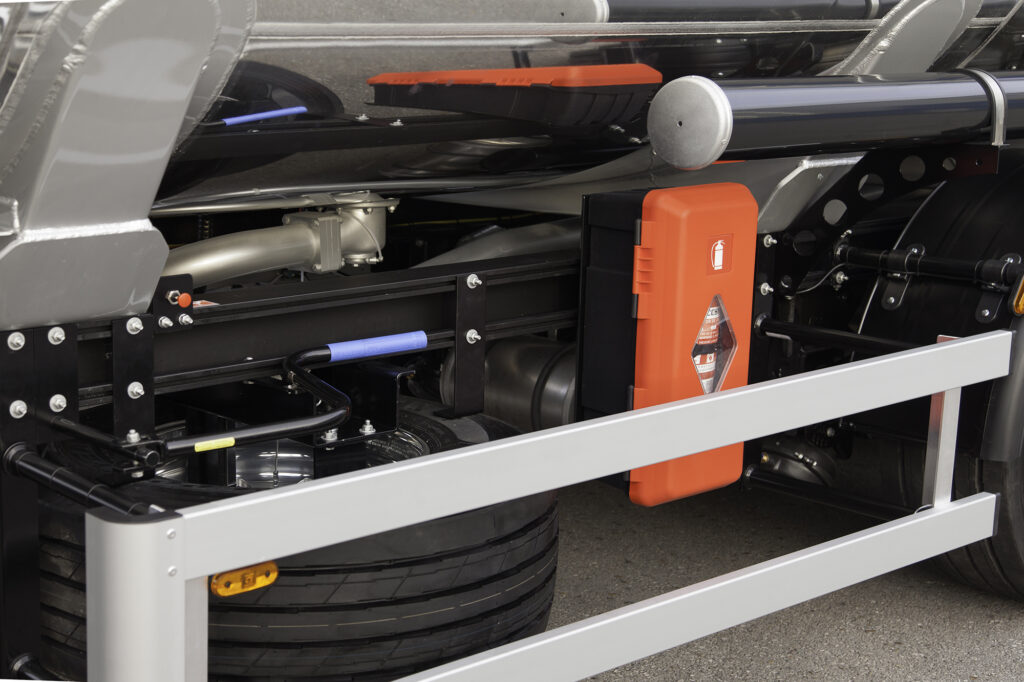

CKD SKD System

This is a modular manufacturing system which views the vehicles as a set of parts (tank, chassis, axle assembly). These are manufactured independently and assembled at a later stage using bolted seams, thereby reducing the maintenance costs of the tankers, making it easier to repair them, and allows all the pieces to be standardized.

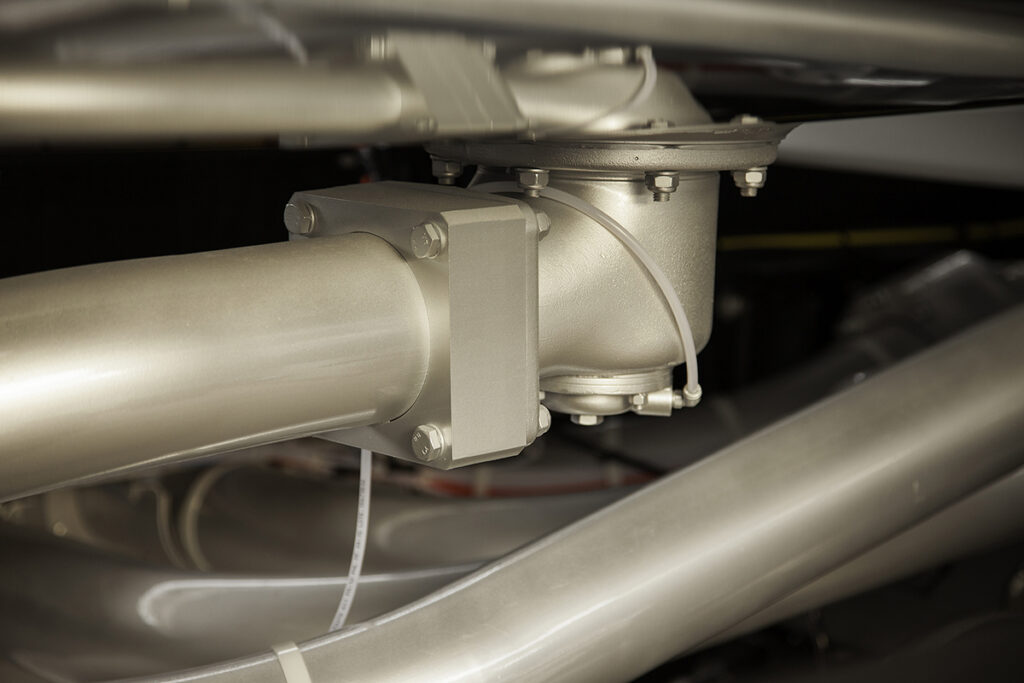

Non-welded pipes

COBO incorporates a technology that allows all its pipes to be developed without the need for welded joints, neither in elbows, nor in clamping flanges to the valve.

This innovative system achieves the total elimination of stresses and fatigue typical of welded joints, the reduction of discharge times due to the elimination of the typical interior clearances of the welds and the ease of assembly and disassembly of pipes in the maintenance and inspection work.

For this innovative solution, a new valve design and all the necessary elements of the pipes have been developed.

Manufacturing linings

With this new manufacturing process, COBO has developed a process to build the exterior and interior linings, which combines beading with hydro-forming. This way, they can obtain linings with a perfect dish end flange finish, a more homogeneous distribution of the displacement of the tensions, with no difference in geometry. It also offers greater versatility of the materials that can be used such as aluminium, carbon steel, stainless steel, or other alloys.

Sealing system

Used for over five years by many hazardous goods road transport fleets, this equipment can be incorporated into their tankers if required. As it is a COBO-designed system, the company is able to supply the parts directly, and also attend to the post-sales service.

COBO-designed compartment equipment

The company has developed its own line of COBO brand compartment equipment. This equipment is installed into their tankers by default, although the customers can always decide if they would prefer to use equipment from other manufacturers. Having their own line of equipment means they can supply parts and post-sales services directly.